|

| Forward half of hull lifts clear of work table Thursday and was then set on the transporter at left. (Rich Ellefson photo) |

This week was notable for the variety of milestones in the Madonna construction progress.

Wednesday Rich Ellefson visited Fabick CAT in Green Bay, where Twin Disc reduction gears were on the floor, awaiting painting to match the CAT yellow of the engines. Once hydraulic pumps and coolant piping connections are verified, the units will be mated and then trucked to the Sturgeon Bay shipyard. Shipyard Engine installation plans call for lifting each engine/gear unit into the hull by means of the large graving dock gantry crane, immediately after the stern section has been turned to its upright position. Actual engine installation with bolting and alignment may come much later, but the lift will be opportune while the crane and the hull are side-by-side. This should be accomplished early in the week of January 6th.

|

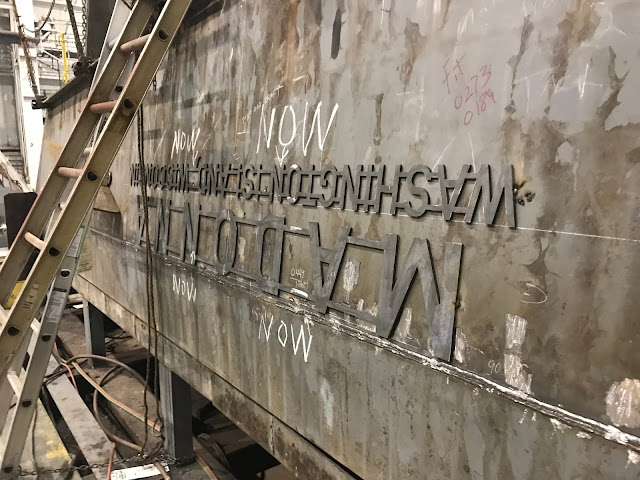

| Vessel name, Madonna, and hailing port, Washington Island, have been applied to the hull transom. |

|

| View of the starboard bow and one of several hinges used to attach the bow ramp. Two U-shaped channels (at right) provide rub rail (fender) protection around the vessel rail. |

Once hovering above the shop table, the bow section was maneuvered by overhead crane to a nearby, multi-axle transporter. From there, the transporter rolled through the yard's South Gate to the former Palmer Johnson construction building off Second Street (now a part of Fincantieri's production facilities.)

The next morning letters that had been cut for the vessel name and hailing port were tacked in place on the transom.

That name, MADONNA, is now official!

Friday morning, Dec. 20th, Rich and Hoyt toured general construction progress. One challenge moving forward will be testing of the watertight integrity of bulkhead and hull welds, to determine there are no leaks. Such testing can be accomplished by yard personnel providing air pressure to a closed space, or training a stream of water from a fire hose against the hull's exterior. Visual examination ensues, inch by inch where each critical weld exists, using the method preferred by the U. S. Coast Guard inspector on site. Each test can be hours long in both set-up and execution. They are critical in obtaining Coast Guard approval, and must be done before painting of seam welds can begin. Tasks that may "bury" areas from inspection, such as piping, wiring or insulation, must come after such inspection. Testing procedures employed on the bow half will be applied similarly to the stern half after roll-out.

|

| View into the inverted engine room of stern half of hull, after the bow section was removed and transported to another building. |

|

| Rich Ellefson inspects the stairway leading from main to upper deck. |

1 comment:

It's great to see her name and home port on the transom!

Post a Comment